SOAP PRESSES - SOAP STAMPERS

We started producing soap presses and soap stampers seventy years ago: Condor is our most famous model. In these years we have sold, all over the world, more than one thousands soap stamping machines for any kind of application: Toilet Soap, “Combo” and Syndet Products, Hotel Soap, Translucent Soap, Laundry Soap and Irregular specialty shapes.

STAMPEX SOAP STAMPER

Following the best tradition of Italian soap machinery manufacturers and core mission of SAS Company, we are pleased to present the world most complete family of flash-stamping soap presses accounting of 8 models for all kind of production needs.

On 2000 we quit the production of the Condor soap presses and introduced the first soap stamping machine of the Stampex family. Thanks to its very positive acceptance, the family grew rapidly with versions with different features and capacities.

Besides the standard versions, from Stampex/1 to Stampex/4 we developed a special series of soap stampers, from Stampex/3+ to Stampex/8+ featured by the Double Stroke stamping action.

With eight different Stampex soap stampers models available plus many other soap press models we confirm our unique position of most specialized soap stamper manufacturer in the world with decades of field experience and one thousand units sold worldwide.

The main vertical stamping movement of all Stampex versions is obtained without cams to assure maximum sturdiness and simplicity; the + versions take advantage of a toggle-joint cinematic mechanism that allows the Double Stroke action for a high finishing quality at any speed rate.

The Stampex/1 and Stampex/2 soap stampers have been studied for small production lines or hotel size soap lines.

The Stampex/3, Stampex/4 soap stampers and the related + versions are suitable for lines from 1,000 to 2,000 kg/h.

The Stampex/6+ and Stampex/8+ soap stamping machines are offered for high-speed soap finishing lines.

Our Stampex are also used to produce solid shampoo bars.

CONDOR SOAP STAMPER

Starting from the Seventies our company SAS MARIANI became well known to many soap companies thanks to the special performances of the CONDOR soap stamping machine, we sold 220 units in several years. Such model has been the first flash-stamping multi-cavity soap press in the world, then this technology spread and now the great majority of the toilet soap is flashstamped.

We then introduced another family of flash-stamping presses, the Stampex and discontinued the manufacture of the CONDOR presses but without forgetting their special features.

In the most recent years, we assist to a development of the soap market with products that are more and more sticky and soft, so the extraction of the stamped bars from the cavities is seldom a challenge even with dies of special material are used.

The stamping process of the CONDOR, thanks to the simultaneous operation of feeding, stamping and extraction, allows a more comfortable and positive removal from the cavities and a reduced impact to the de-flashing plate where the soap excess is more gently separated from the stamped bars. We therefore wanted to re-design the same process and are proud to present a family of CONDOR presses of different capacities from 200 to 500 stamped bars per minute.

Our Stampex family is still offered for many different applications while we suggest the CONDOR technology when stamping:

- SHAMPOO BARS which are usually soft, sticky and sometime of special shapes

- SYNDET BARS in general

- Translucent Soaps

- 100% “coconut” soaps

- RIM-BLOCKS

- Products with irregular shapes

- Soap Bars of Cosmetic quality

STAMPING PROCESS

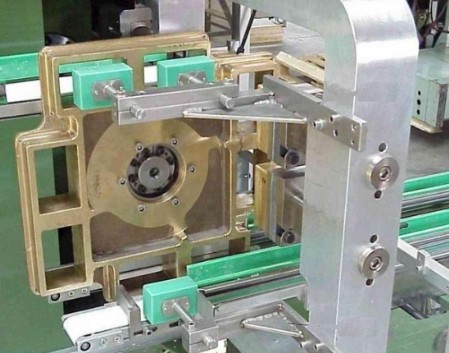

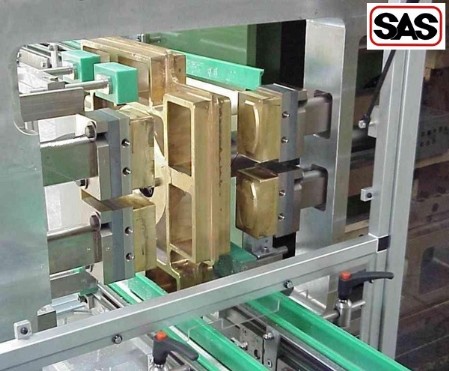

The main vertical stamping movement is obtained with a toggle-joint mechanism (no cams) to assure the maximum sturdiness and simplicity.

The action of stamping is with double-stroke, this assures a superior finishing and the stabilization of the shape.

The bottom rotating mandril has four stations, each station has a single operation:

- Loading of billet

- Stamping into bars

- Extraction of stamped bars

- Separation of any flashing, if necessary

Each of these operations can be accurately performed because they are not in sequence but are done in parallel.

The unique feature of the movable de-flashing plate is of great help to allow a delicate separation of the flashing at low relative speed.

The CONDOR press takes advantage of the latest technical developments in terms of solutions and materials. As well as the Stampex press, it has an intermittent infeed conveyor, a customized discharge conveyor, cooling circuits for the die sets, circuits for compressed air and vacuum.

CUBEX SOAP STAMPING MACHINE

The renewed interest in cubic shapes, prompted us to offer the "CUBEX" family of presses consisting of these main models:

•CUBEX/2P - Stamping the soap bars on 2 sidesPneumatic version applicable for small production requirements.•CUBEX/6P - Stamping the soap bars on 2,4 and 6 sides ("Marseille" Soap Shape)Pneumatic version applicable for small production requirements.•CUBEX/2M - Stamping the soap bars on 2 sidesMechanical version applicable for medium production needs. (For larger production needs we recently developed the "LAUNDREX" soap press with revolving rotary die-box)•CUBEX/6M - Stamping thesoap bars on 2,4 and 6 sides ("Marseille" Soap Shape)Mechanic version applicable for medium-large production needs.•CUBEX/6M DUPLEX - Duplex version of the CUBEX/6MMechanic version applicable for large production needs, 120 soaps per minute. Die-sets have cooling channels for best stamping quality and efficiency. Existing "Artiglio" special die-sets used on Serenia and Volpe can bee used on CUBEX presses on request.

OVALEX SOAP PRESS

The “OVALEX” is a fully automatic soap press designed to stamp toilet bandless soap bars, banded soap bars and specialty shaped soap bars. It is pneumatically operated and is an ideal solution for small-medium production requirements.

LAUNDREX SOAP PRESS

This soap stamping machine is suitable to engrave on two sides both laundry and toilet soaps, banded rectangular shape.

The rotating die box has four stations each one with two cavities; each stroke gives two stamped soap bars.

Dual-lane infeed conveyor and single lane discharge conveyor complete the standard version.

Dual-lane infeed conveyor and single lane discharge conveyor complete the standard version.