PAPER SOAP WRAPPERS

High speeds require continuous motion: the PAPER family of soap wrappers process the incoming toilet soap bars without stopping them in any phase of the feeding, wrapping and sealing process. This allows to reach speeds of up to 600 soap wraps per minute meeting the needs of the very high speed lines. These performances are possible thanks to the full integration of the wrapper with the upstream soap press: the novel ELAX solution gives the advantages of the existing direct transfer units eliminating their rigidities.

The superior design of this machine comes from the many experiences that we did when rebuilding existing high speed soap wrappers and understanding their limits. Thanks to the continuous presence of our company in the soap wrapping machine business, we have the necessary expertise not only to manufacture such very powerful machines but also to service them and assure a prompt and positive after-sale service.

PAPER/600 Toilet Soap Wrapper

MAIN FEATURES:

- SPEED: up to 600 wrapped soaps per minute.

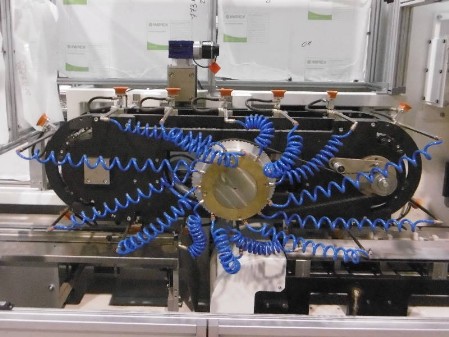

- ELAX or IN-LINE SOAP FEEDER – Depending on the application, the required speed and the need to be interfaced with an existing soap press, the PAPER wrapper could be completed with a direct transfer or a soap feeder. In the first case the position of each soap bar is kept known all the way from the press to the wrapper thanks to an innovative solution and an Electrical Axis, in the latter case the incoming bars are to be timed for the wrapper by means of a set of belt conveyors. The final step is a rotary Carousel of suction-cups which lift the timed soap bars, rotate them and safely place in the infeed chain of the wrapper.

- SPLICERS – Very useful tools to avoid the repeated stop of the production line for the substitution of reels.

PAPER/500 Toilet Soap Wrapper

MAIN FEATURES:

- SPEED: up to 500 wrapped soaps per minute

- ONE LANE IN-LINE SOAP FEEDER – It consists of a set of belt conveyors and a set of vacuum suction-cups which pick up, rotate and release the incoming soap bars into a pocketed conveyor. The position of the incoming bar is detected electronically and through an integrated automatic system picked up in a way to guarantee a damage-free transfer of the bar soap through the whole cycle. Height adjustment for size change. The group is driven by the wrapper.

FEATURES OF BOTH MODELS:

- OUTER WRAP FEEDER complete with two reel holders. The reel holders are completed with a fully automatic pneumatic core locking system.

- INNER STIFFENER FEEDER complete two reel holders. The reel holders are completed with a fully automatic pneumatic core locking system.

- Main WRAPPING AREA consisting of:

- Outer wrap and stiffener cutting group

- Timing Belt holding multiple Pincers

- Timing Belt holding multiple Grippers

- Fixed and high-speed movable folders

- SEALING AREA & OUTLET consisting of side belts conveyors with heating elements and cooling elements. The wrapped soap bars are delivered right-side up to the down-stream equipment.

- ELECTRONIC LINK with upstream stamping machine for Soap Flow Control for maximum operating efficiency and minimum use of the NO FEED - NO WRAP system.

ELECTRIC & ELECTRONIC PANEL complete with Touch Screen, PLC, Servo-Driven motors, etc. and on board installation of various sensors for the following operations:

- “NO FEED – NO WRAP” automatic operation

- sealing and cooling belts with independent drive synchronized with the machine. This allows to seal and discharge the wrapped tablets also during machine stops.

- temperature control system for each individual heating element

- photocell to detect the soap presence on the pocket conveyor for “no feed – no wrap” operation

- device to detect un-proper position of the soap bar on the pocket conveyor with automatic machine stop

- control device for positive transfer of cut sheets to the wrapping area

- control device for both outer wrap and product pliers

- overload system for the back folder in case of product jam

- overload system on the product pliers in case of product jam against the bottom fixed plate

- mechanical overload safety device for machine main drive

- machine design and manufacture following the CE standars

- Interlocked and ergonomic Safety Covers

- noise level at 1 mt. distance from machine: less than 78 DbA

- User friendly changeover with handwheels including:

- adjustment of the pocketed infeed belt (bottom pocket, front holding belt flight and side guides)

- adjustment for paper gripper assembly (both axial and longitudinal)

- height adjustment for paper gripper and product holding and wrapper folding group

- adjustment for extraction side belts (width and height)

- width adjustment of sealing-cooling belts