SOAP DRYER

We are pleased to present our Soap Vacuum Spray Drying Plants for the production of toilet soaps noodles (soap-pellets) and laundry soap bars. For Soap Noodles manufactruing of medium/high capacity and all the times that is required or preferred a Vacuum Drying Plant is a well-proven route. We offer brand-new Vacuum Chambers of new generation for easy operation and maintenance.

• We design, manufacture and supply Soap Vacuum Spray Drying Plants

• We also revamp existing Plants and supply fully rebuilt second-hand Soap Drying Plants

• Spare parts, pumps and other components for existing Soap Drying Plants are available.

• Customized Engineering Services are offered and plants for special application are developed jointly with the customers.

• Start-up and training by experienced technicians are available when required.

• We also revamp existing Plants and supply fully rebuilt second-hand Soap Drying Plants

• Spare parts, pumps and other components for existing Soap Drying Plants are available.

• Customized Engineering Services are offered and plants for special application are developed jointly with the customers.

• Start-up and training by experienced technicians are available when required.

The SAS team looks forward to the opportunity of designing a Soap Drying Plant which meets your specific needs. Contact us with your needs. We will be pleased to work with you.

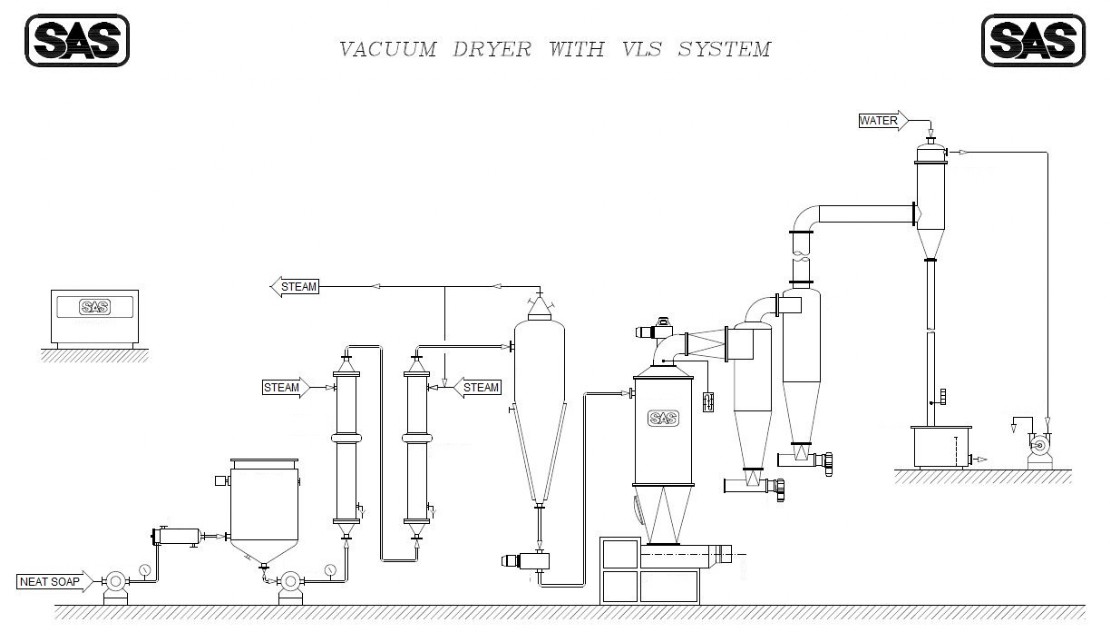

The neat soap from Saponification Plant is pumped to the Soap Drying Plant through the Heat exchanger by means of Soap feed pump. The soap enters in the Vacuum Liquid Separator (VLS), where a part of vapour is separated from the soap; this vapour is conveyed in the Heat Exchanger, or it is recycled and used as utility. The soap is pumped in the Vacuum Chamber where it comes in contact with the wall of the Vacuum Chamber. Conditions inside are such that the soap dries, cools down, and is immediately scraped off the wall.

Evaporated moisture is conveyed through vapour ducts and cyclones to the Barometric condenser, where all the vapours are condensed by direct contact with the water from cooling tower. All this water falls, through barometric condenser, into the Hot Well.

In some cases, the vacuum levels obtained by the basic vacuum group are not enough or due to environmental conditions (high wet bulb temp determining a not enough cold cooling water) or when a very cold dried soap is required; in such cases it becomes necessary the use of a Booster that guarantees ulterior pressure drop.

Eventual un-condensable, such as air, are sucked by a Liquid Ring Vacuum Pump group.

During passage through the Cyclone/s, vapours are separated from entrained soap dust which is gathered at the bottom of the Cyclone/s and transferred outside the Plant by Soap Fine Screw Extruder/s or it is gathered inside dust drum connected to the bottom of the vessel.

Once scraped from the walls of Vacuum Chamber, the soap falls into a Simplex Plodder (or Duplex Vacuum Plodder) which extrudes the soap in form of soap noodles (or soap bars).

In some cases, the vacuum levels obtained by the basic vacuum group are not enough or due to environmental conditions (high wet bulb temp determining a not enough cold cooling water) or when a very cold dried soap is required; in such cases it becomes necessary the use of a Booster that guarantees ulterior pressure drop.

Eventual un-condensable, such as air, are sucked by a Liquid Ring Vacuum Pump group.

During passage through the Cyclone/s, vapours are separated from entrained soap dust which is gathered at the bottom of the Cyclone/s and transferred outside the Plant by Soap Fine Screw Extruder/s or it is gathered inside dust drum connected to the bottom of the vessel.

Once scraped from the walls of Vacuum Chamber, the soap falls into a Simplex Plodder (or Duplex Vacuum Plodder) which extrudes the soap in form of soap noodles (or soap bars).